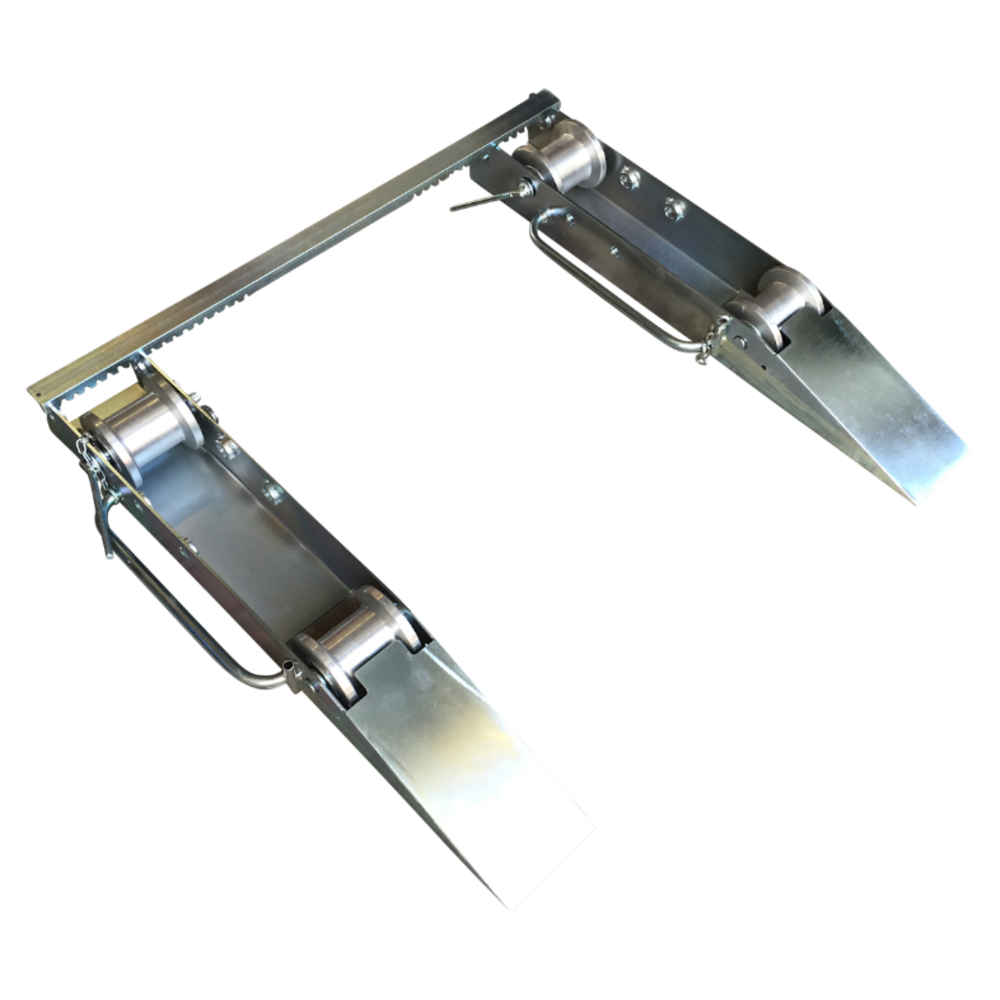

Why our lines are more than just a piece of technology

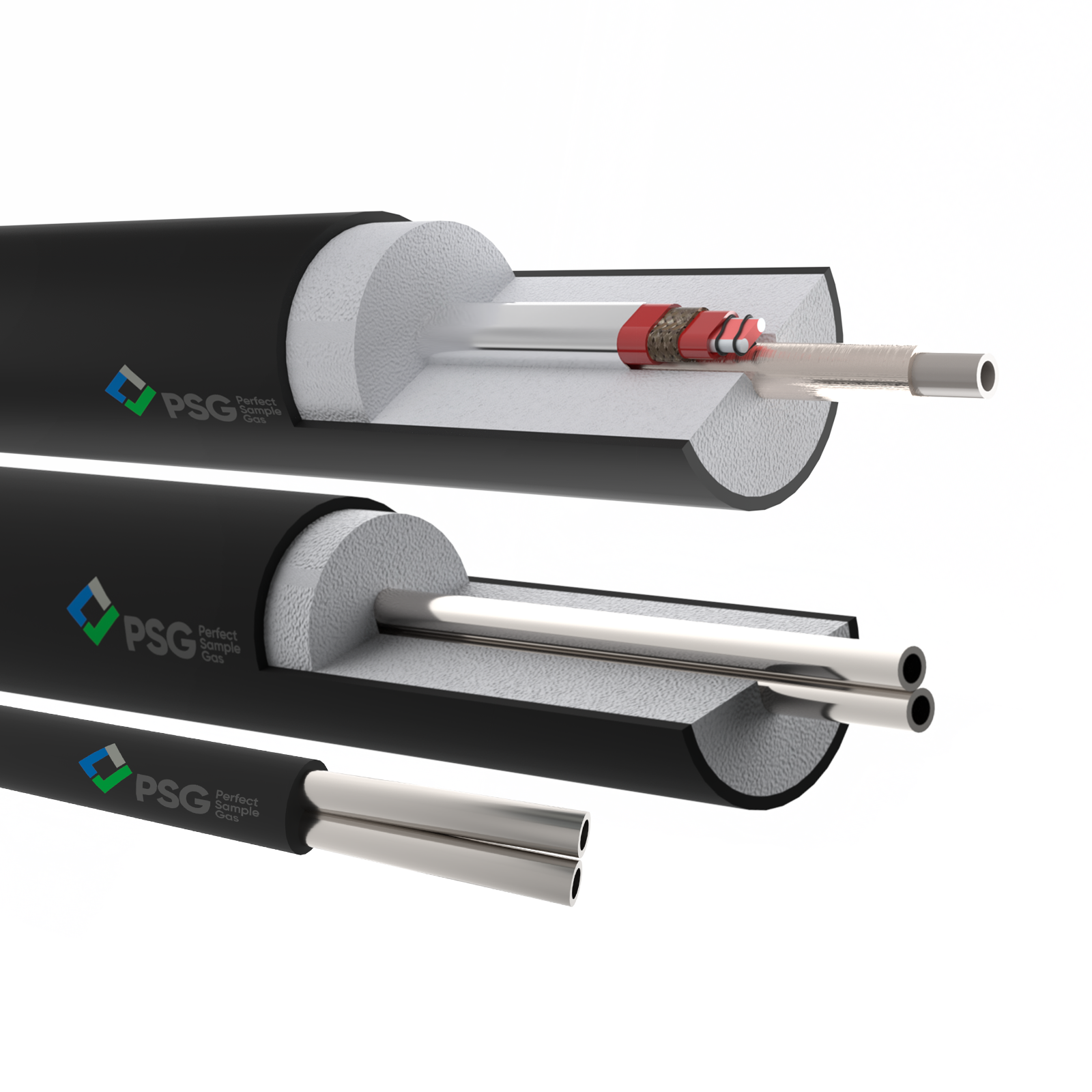

Our heated lines are far from standard off-the-shelf parts. Every detail is carefully considered – for safe, efficient and low-maintenance applications in gas analysis.

Developed and produced in Germany.

* TPU = thermoplastic polyurethane, PE = polyethylene, PVC = polyvinyl chloride

How PSG lines make your work better and easier

Less worry, more control. Whether extractive emission measurement technology (CEMS) or demanding industrial processes: With our lines, the sample gas remains at exactly the right temperature – even under extreme conditions. No condensation. No CO baseline. No discussions during an audit.

Process clarity

Stable sample transport = reliable measurement results

Cost efficiency

Up to 25% less energy consumption over the life cycle

Regulatory compliance

Meets what standards require – and what auditors expect

Technical advantages in comparison

Thanks to the combination of extruded construction and intelligent heating technology, PSG lines often pay for themselves in the first year of operation.

| Feature | Classic PA12 line | PSG extruded line |

|---|---|---|

| Energy consumption | 90 W/m | 60 W/m |

| Heating circuit length | up to 60 m | up to 100 m |

| Can be shortened | no | Can be adapted on site |

| CO baseline | negligible | negligible |

| ATEX zone | limited | Certificates for the entire assembly (patented Ex²/Ex³ technology) |

* Polyamide 12 corrugated cable

Frequently asked questions (FAQ)

Enquire now and get advice

Do you have a specific application or need a technical assessment first? Our team is ready to help.

Made with confidence in Germany | ATEX-certified | Over 50 years of experience in gas analysis