Properties

Application

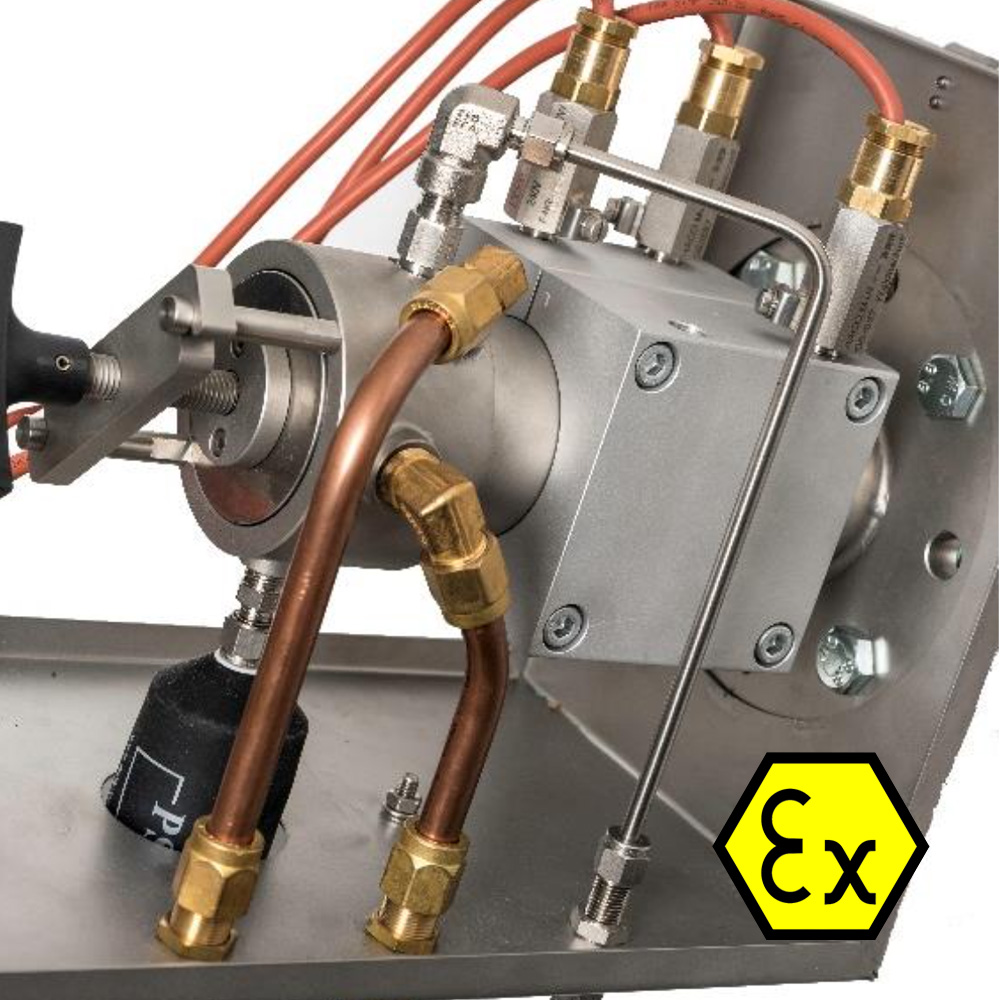

The diaphragm sample gas pump PSP87 ATEX is used for continuous extractive gas analytics in explosion zones. It mainly serves for unadulterated sucking and pumping of highly aggressive and corrosive sample gas from sample point to the analyzer house resp. analyzer. Typical applications are emission measurements e.g. in waste incinerations and process measurements e.g. in chemical, petro-chemical, steel-, glass- or cement-industry.

Technology

The PSP87 ATEXis a reliable diaphragm pump with compact dimensions that guarantees an optimum integration in systems and devices. It has a highly gas tight PVDF-pump head whose components have been developed especially for pumping of aggressive and corrosive gases. Special valves made of FFPM ensure a high tolerance to vapor and condensate. The patented PTFE-coated diaphragm was optimized using the finite-element-method. The results are an extremely long lifetime of the diaphragm and a high pneumatic performance of the pump. The pump is operating absolutely oil-free and ensures therefore an unadulterated pumping, evacuating and compressing of gases. The pump is ready for mounting and can operate in any position.

Functions

Core of the PSP87 ATEX is the elastic diaphragm which is moved up and down in its center by an eccentric. In this way gas is pumped through self-opening and-closing valves. Due to the IP66 housing the pump is protected perfectly against spray water, dust and dirt.