Properties

Application

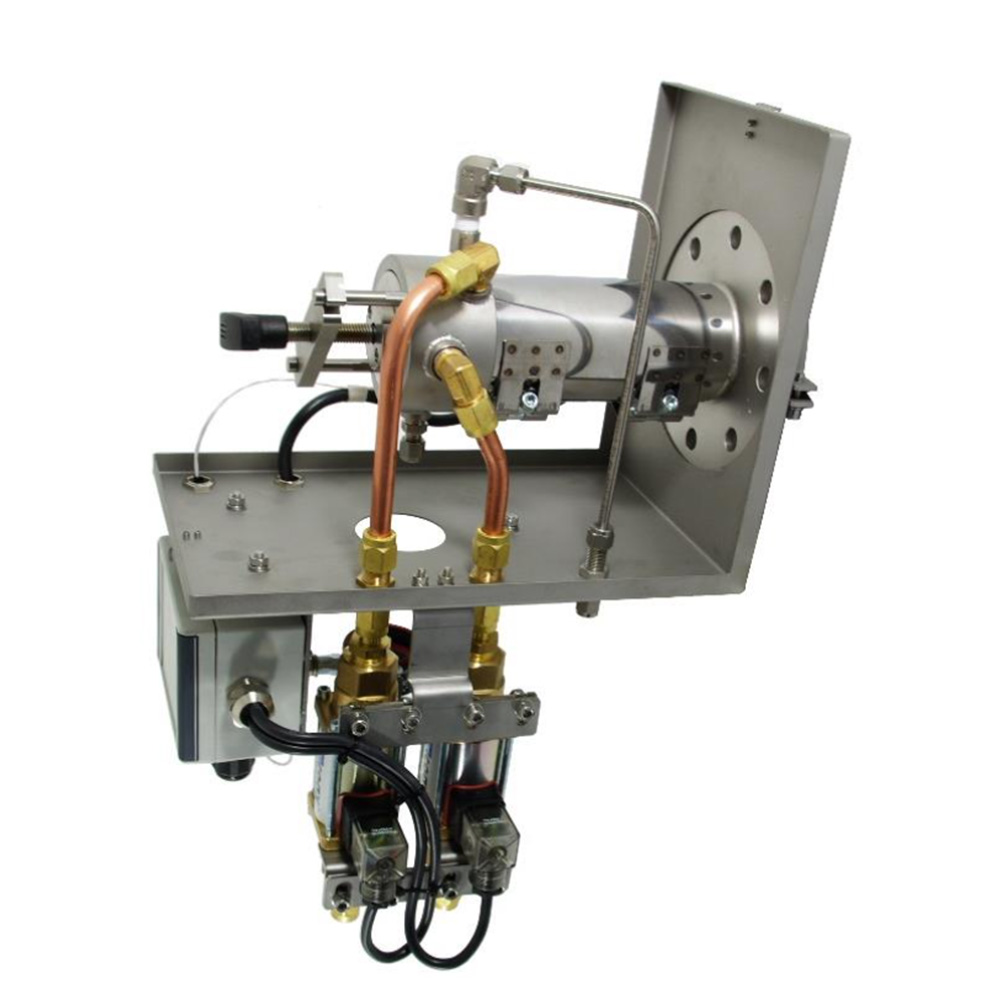

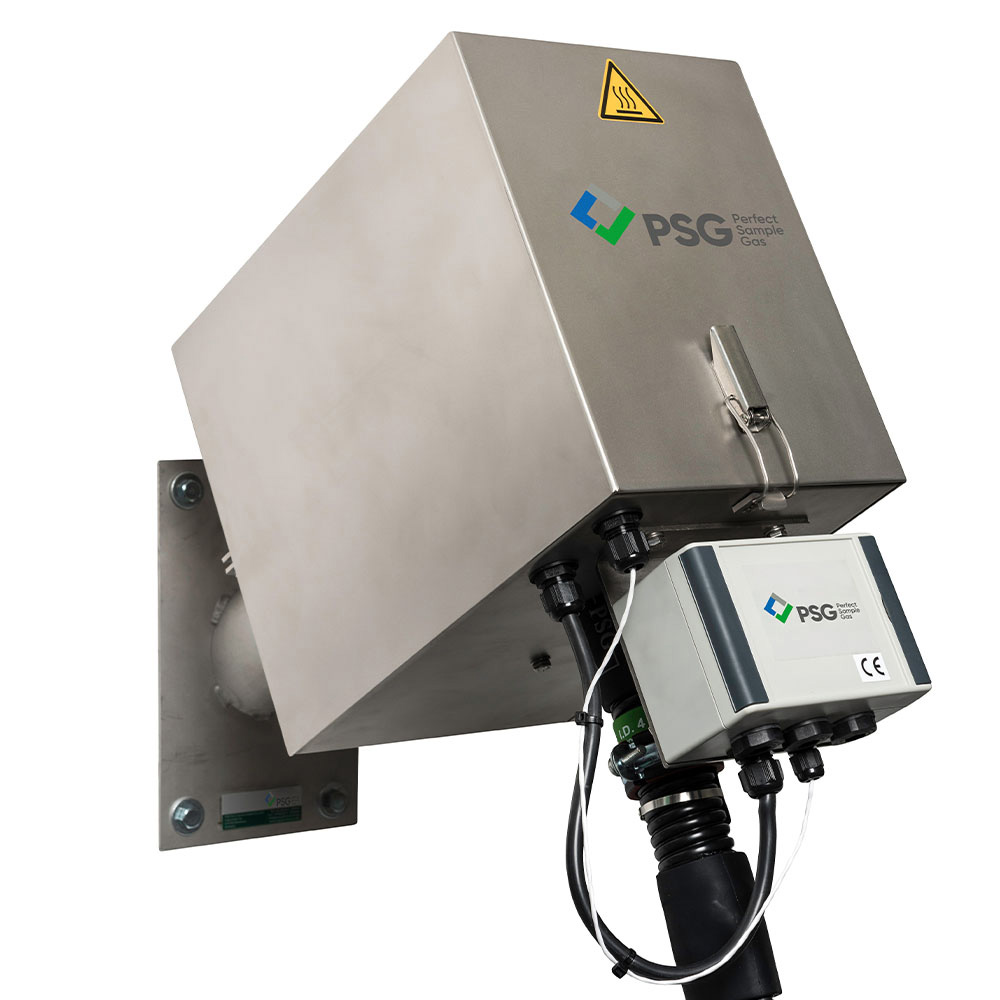

The heated gas sampling probes of thePSG Plus Probe DeNOX series are used for continuous extractive gas analysis. They are used for the trouble-free representative sampling of hot heavily dust and water vapour loaded gases. Typical applications are DeNOx processes (SCR) in which NH3 is added to the flue gas to reduce the NOx content.

Technology

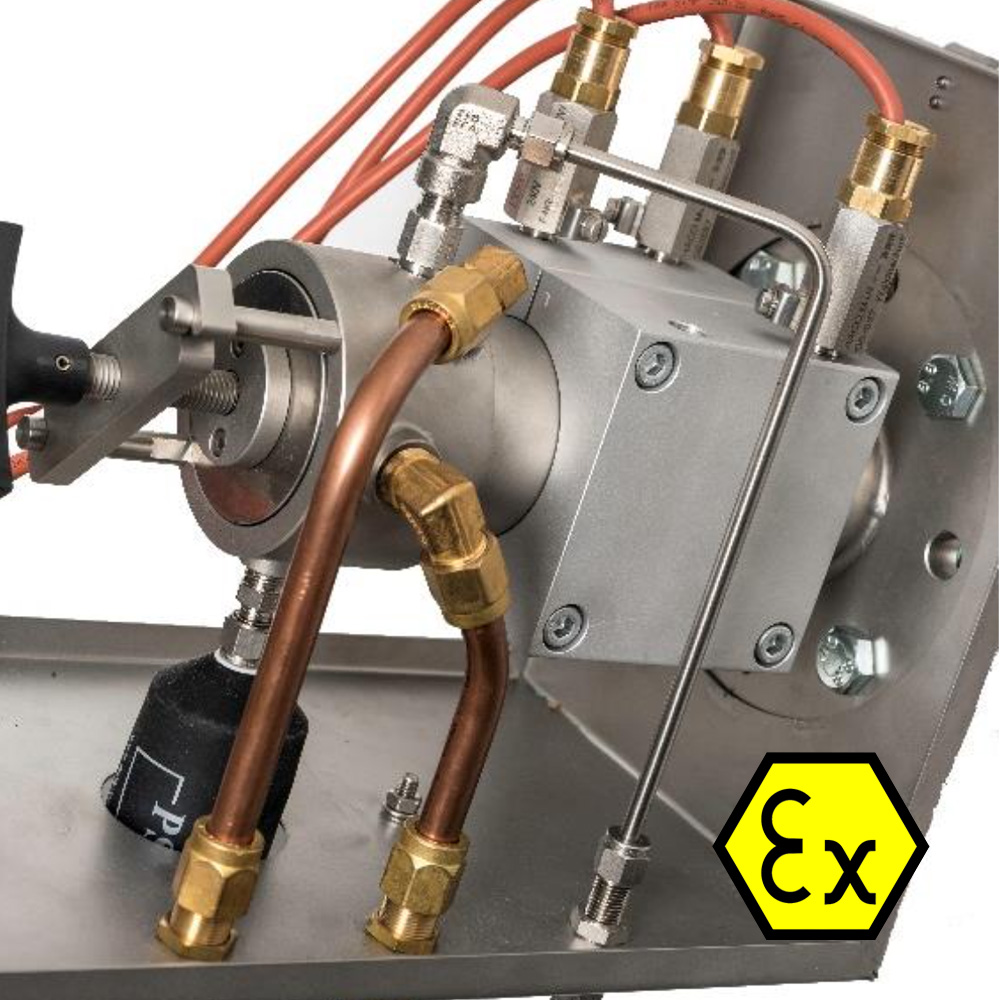

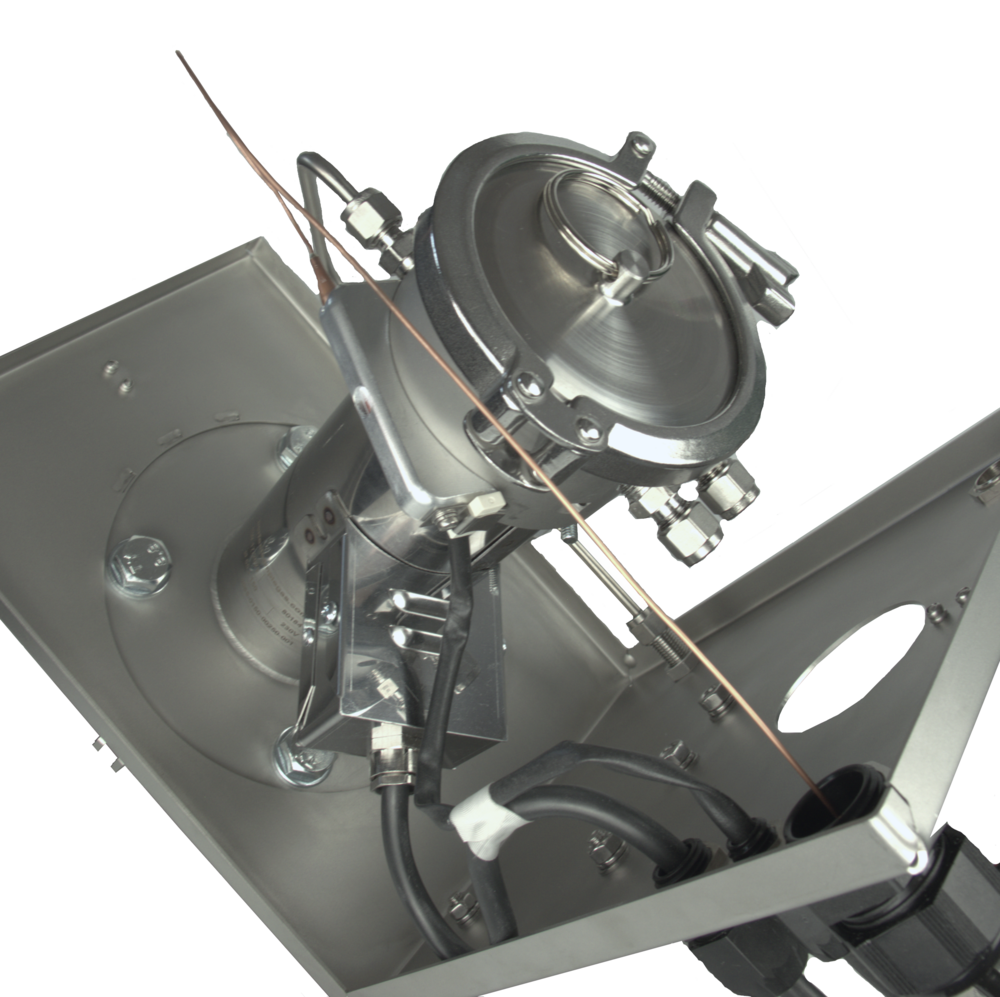

The PSG Plus Probe DeNOx probes are based on the PSG Plus probe series. With the market’s largest filtration surface of 212 cm. and the dual stage back purging with 12×1 mm tubing, which is controlled via two Coax solenoid valves with 10 mm passage, this enables operation in high dust concentrations of up to 280 g/m.. In combination with the full-surface, close-fitting heating sleeve and the thick-walled glass-fibre insulating jacket, which enables homogeneous heating of the PSG Plus Probe DeNOx to 180°C, dust is reliably separated without condensation of water vapour and therefore without blocking of the filter. The membrane coated ceramic filter with 0,3 µm porosity additionally supports the great back purge effectiveness.

Functions

For use in DeNOx processes, the PSG Plus Probe DeNOx is also equipped with a glass condensate vessel. This is filled with glass balls to increase the surface for the saltification. The condensate with dissolved ammonium salts is removed via the built-in peristaltic pump type SR25. Due to the hot gas flow, the temperature of the condensate vessel is higher than the ambient temperature. In order to determine the loss of measuring components, the PSG Plus Probe DeNOx is equipped with a test gas inlet including piping. The built-in protection against accidental contact ensures safety. Thanks to the intelligent design, both the filter change and the maintenance of the separating vessel can be carried out quickly and without tools.